What Are Cookies

As is common practice with almost all professional websites this site uses cookies, which are tiny files that are downloaded to your computer, to improve your experience. This page describes what information they gather, how we use it and why we sometimes need to store these cookies. We will also share how you can prevent these cookies from being stored however this may downgrade or 'break' certain elements of the sites functionality.

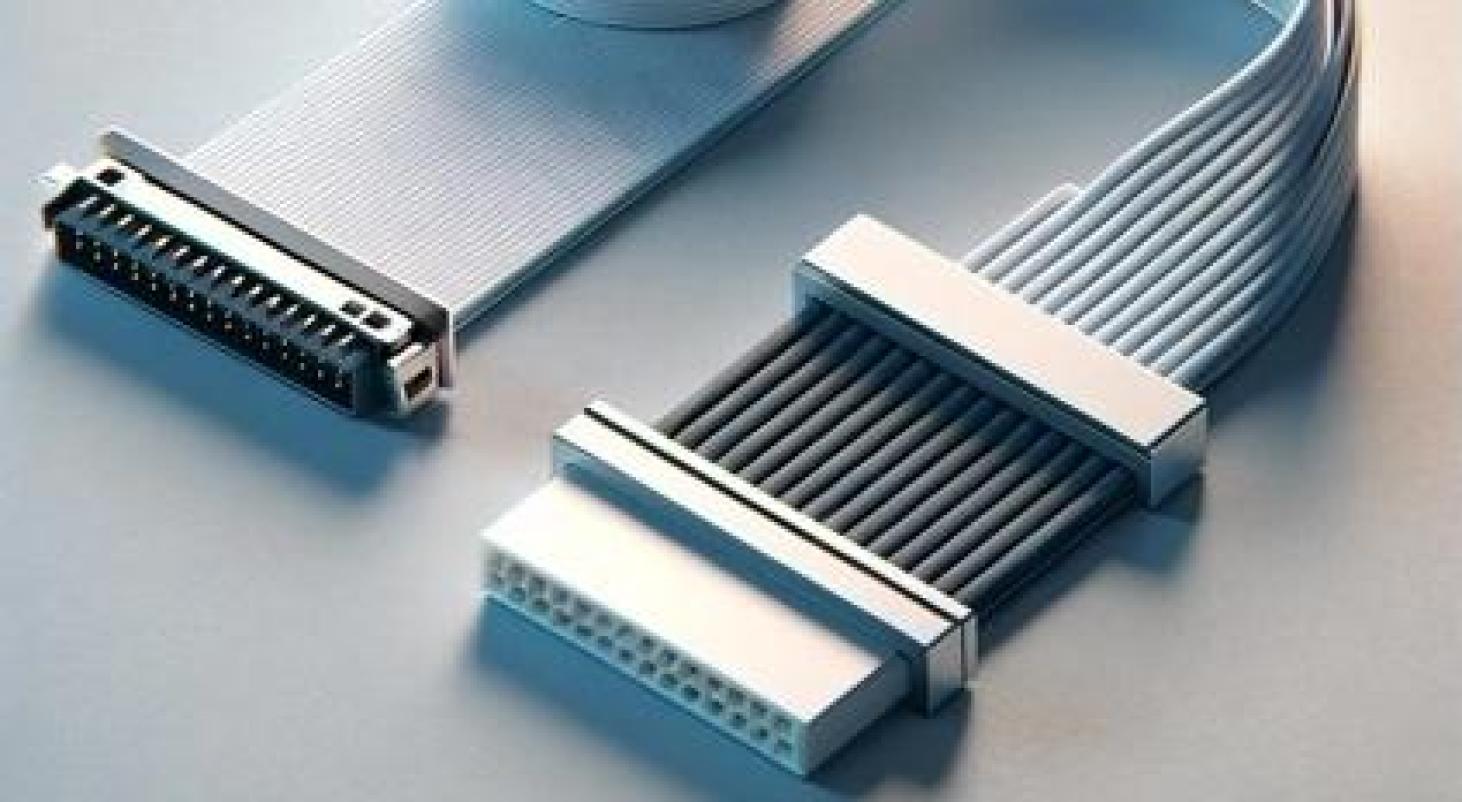

Flat Cable Assemblies

Y.C. Cable is a trusted manufacturer of flat ribbon cable assemblies, delivering high-performance solutions since 1985. With state-of-the-art facilities in China and the U.S., we provide a wide range of customized flat and round ribbon cable assemblies—built to your specifications and tested to meet global standards.

What are Flat Cable Assemblies?

Flat cable assemblies are typically assembled, tested, and packaged together with IDE, SCSI, Serial ATA, or D-sub connectors based on customer design drawings or bill of materials. A flat cable is a wide cable in which multiple wires or conductors are tied together with a flat wide band — hence the name. Flat cables look like ribbons, so people also call them to ribbon cables or flat ribbon cables. USB ribbon cables and round ribbon cables are available in Y.C. CABLE.

Flat Cable Wire for Flat Ribbon Cable Assemblies

Flat cable wires are used in flat ribbon cable assemblies because of their unique physical properties and design. The flat shape of the cable allows for the efficient use of space and makes it easier to route the cable in tight spaces. Additionally, the flat shape helps to reduce crosstalk between adjacent wires, which can be a problem in traditional round cables where wires are tightly bundled together.

The design of flat cable wires is such that they have a very low profile, meaning that they are very thin and can be easily folded or bent without damaging the cable. This is important in applications where space is at a premium, such as in electronic devices or computer systems.

Flat cable wires are also known for their high flexibility, which allows them to be bent and twisted without losing their integrity. This flexibility makes them ideal for applications where the cable needs to be moved or adjusted frequently.

How to Make Flat Ribbon Cables?

-

Cut the wires: Start by cutting the individual wires to the desired length. Use a wire cutter or scissors to ensure clean cuts.

-

Arrange the wires: Once the wires are cut to length, arrange them side by side in the order you want them to appear in the cable. Make sure they are straight and parallel.

-

Add a connector: If you need a connector on one or both ends of the cable, attach them now. There are several types of connectors available, including IDC connectors and crimp-on connectors.

-

Attach the wires: Use a ribbon cable crimping tool to attach the wires to the connector. The tool will ensure that the wires are correctly aligned and securely attached to the connector.

-

Insulate the cable: Once the wires are attached to the connector, you can add insulation to the cable if needed. This will protect the wires from damage and help to prevent interference.

-

Test the cable: Finally, test the cable to make sure it is working correctly. Use a multimeter or other testing equipment to check for continuity and proper wiring.

The Advantages of Flat Ribbon Cable Assemblies

- Saves Space: Flat ribbon cables have a higher packing density than ordinary round cables. Therefore, in much new aviation and other equipment, the flat ribbon cable is used to make it more applicable to equipment with narrow space.

- Light Weight: Due to the stacking of flat ribbon cables and the simplification of fixtures and supports, the weight in this respect is lighter than that of round cables. In addition, the conductor made into a pin-type connector is much lighter than the round connector.

- More Flexible: Flat cables have a larger bending amplitude. So in some cases where the cable is often bent, the flat cable can be applied to avoid breaking due to frequent bending.

- More Reliable: The use of flat conductor ribbon cables for interconnection ties improves reliability in some ranges. The high tensile strength of the insulation and the planar structure provides for uniform stresses on the cable, improving resistance to operating and dynamic workload. The advantages are even more significant when using smaller conductor sizes. Flat cables have fast heat dissipation so they can reduce operating temperatures and have proven to be reliable in many applications.

- Small Size: The high tensile strength of the insulation and the flat structure make the cable evenly stressed and improve the ability to withstand operation and dynamic workloads. When using smaller-sized conductors, the termination of the flat cable is easy to mechanize, simple, and reliable.

- Lower Costs: The material costs, design, and development costs, manufacturing costs, and installation costs play an important role in reducing costs.

- Stronger: Due to the uniform stress distribution and the increased strength of the flat cable, the structural strength is improved, so the cross-sectional area of the conductor can be reduced to the size required for the current capacity. The conductors are easy to separate and can be routed in the circuit.

Flat Ribbon Cable Assemblies Applications

Y.C. CABLE is a leading cable assembly factory that has provided massive flat cable assemblies for many computer factories since 1985. Flat cables are widely used in computers for internal and external connections. We provide various flat ribbon cable assemblies as computer peripherals and in many industries — such as on motherboards, PCB boards, card readers, tape machines, CD drivers, floppy drivers, hard drivers, etc.

Y.C. CABLE has a well-organized assembly department and well-trained assembly members who have extensive experience in flat ribbon cable assemblies and custom cable assemblies. Our team tailors the assembly process according to your specific project requirements and will quickly complete the customized project. Once the order has been placed, our engineering team works closely with customers to formulate detailed and safe work instructions to ensure that we can produce high-quality products every time.

Types of IDC Flat & Round Ribbon Cable Assemblies:

- USB Ribbon Cables

- IDC Round Ribbon Cables

- IDC Flat Cables

- IDE Ribbon Cables

- IDE Cable Assemblies (2, 3, 4 connectors)

- SCSI 1, SCSI 2, and SCSI 3 drive cables

- SCSI Internal

- SATA Flat Cable Assemblies

- Audio Flat Cables

- Internal Round Cable Assemblies

- Round Ribbon Cable Assemblies

- Round to Flat Cable Assemblies

- Coax Hi-Speed Ribbon Cable Assemblies

- D-sub Ribbon Cable Assemblies

- Flat Coaxial Cables

- Flat Coax Cables

- Flat Speaker Cables

- Flat Ribbon cables

- Serial ATA Cables

- Jacketed & Shielded Ribbon Cables

- Extension Flat Cables

- Floppy Cables

- Universal Floppy Drive Cable Assemblies

- Micro D Custom Ribbon Cables

- And more....

Flat Ribbon Cable Assemblies Factories in China and USA

We have multiple facilities in Dong Guan (China), Silicon Valley (California), and Piscataway (New Jersey); with the latter two locations being within the USA. Y.C. CABLE manufactures in accordance with IPC 620 and Telcordia GR-326 specifications, in addition to being ISO 9001:2015 in the USA. Our own factory in China follows ISO 9001:2015 and ISO 13485:2016. This facility in China is ISO 14001:2015 certified as well. We also offer cost-saving manufacturing solutions for components, labor, production, and quick-turn services. All of our products are manufactured and tested in compliance with the following standards: UL/CSA, Telcordia, IEC/ANSI, TIA/EIA, and IPC. We are also members of the Wiring Harness Manufacturer’s Association and BICSI.

Among those flat cable assembly companies, Y.C. CABLE is a professional factory offering a wide range of services. No matter what technical requirements you may have, we are ready to work with you to deliver products on time and provide excellent quality and service support.

Contact us to get a quick quote and more information.

For off-the-shelf cables and accessories, please visit our online store: GRANDMAX.