What Are Cookies

As is common practice with almost all professional websites this site uses cookies, which are tiny files that are downloaded to your computer, to improve your experience. This page describes what information they gather, how we use it and why we sometimes need to store these cookies. We will also share how you can prevent these cookies from being stored however this may downgrade or 'break' certain elements of the sites functionality.

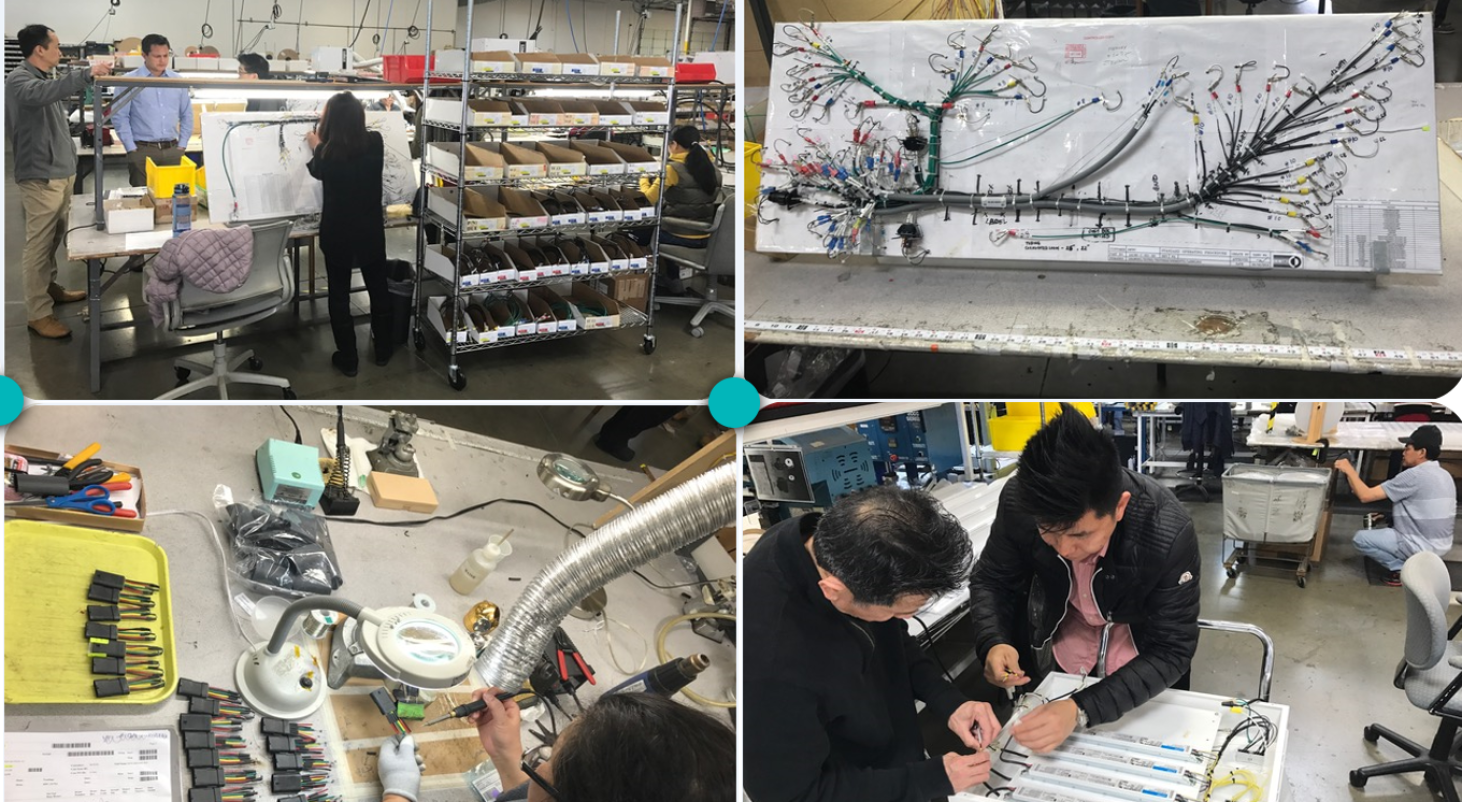

Custom Cable Assembly Services

Y.C. Cable provides custom cable assembly services manufactured strictly according to customer-provided drawings and bills of materials (BOM). We support OEM and industrial customers requiring cable assemblies that cannot be fulfilled by standard, off-the-shelf solutions.

From prototype builds to full production, our focus is precision manufacturing, quality control, and dependable delivery.

What Makes a Cable Assembly “Custom”?

A custom cable assembly is designed to meet unique application requirements such as specific cable types, connector configurations, shielding needs, environmental conditions, or performance standards.Custom cable assemblies are commonly used when standard cable products do not meet electrical, mechanical, or regulatory requirements.

Custom Cable Assembly Workflow

Our custom cable assembly process is structured to ensure accuracy, repeatability, and clear communication:

-

Customer drawing and BOM review

-

Specification clarification and approval

-

Cable preparation and connector termination

-

Assembly, sleeving, or overmolding

-

Electrical testing and inspection

-

Production scaling and final packaging

Each build follows approved documentation to ensure consistency from prototype to production.

Customization Options

Custom cable assembly solutions may include:

-

Cable type and conductor configuration

-

Connector and terminal selection

-

Shielded or unshielded designs

-

Overmolding and strain relief

-

Environmental and durability considerations

-

Labeling and packaging requirements

All options are implemented according to customer specifications.

Prototype to Production Support

Y.C. Cable supports custom cable assembly projects at every stage, including:

-

Low-volume pilot runs

-

High-volume production programs

This flexibility allows customers to validate designs and scale production efficiently.

Industries Using Custom Cable Assembly

Custom cable assemblies are commonly used in:

-

Automotive and transportation systems

-

Medical and laboratory equipment

-

Industrial automation and robotics

-

Telecommunications and networking

-

Consumer and commercial electronics

Assemblies are manufactured to support application-specific operating conditions.

Why Choose YC Cable for Custom Cable Assembly

Customers choose Y.C. Cable because we offer:

-

Manufacturing strictly to customer drawings and BOM

-

Support for prototype through production volumes

-

Controlled manufacturing and inspection processes

-

Clear communication throughout the project lifecycle

-

Manufacturing support in the United States and Asia

Our goal is to deliver reliable custom cable assemblies that meet exact customer requirements.

Request a Quote for Custom Cable Assembly

If your project requires a custom cable assembly, Y.C. Cable is ready to support your manufacturing needs.

Contact us with your drawings, specifications, and BOM details, and our team will assist you in delivering a solution tailored to your application.

To explore our full range of offerings, view our Cable Assembly Solutions.