What Are Cookies

As is common practice with almost all professional websites this site uses cookies, which are tiny files that are downloaded to your computer, to improve your experience. This page describes what information they gather, how we use it and why we sometimes need to store these cookies. We will also share how you can prevent these cookies from being stored however this may downgrade or 'break' certain elements of the sites functionality.

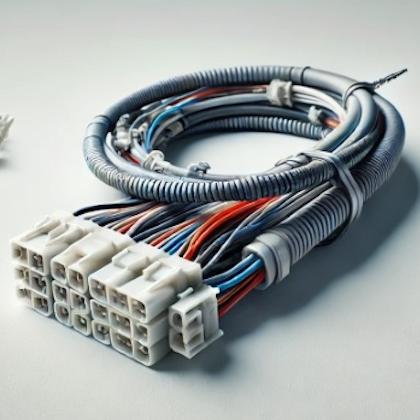

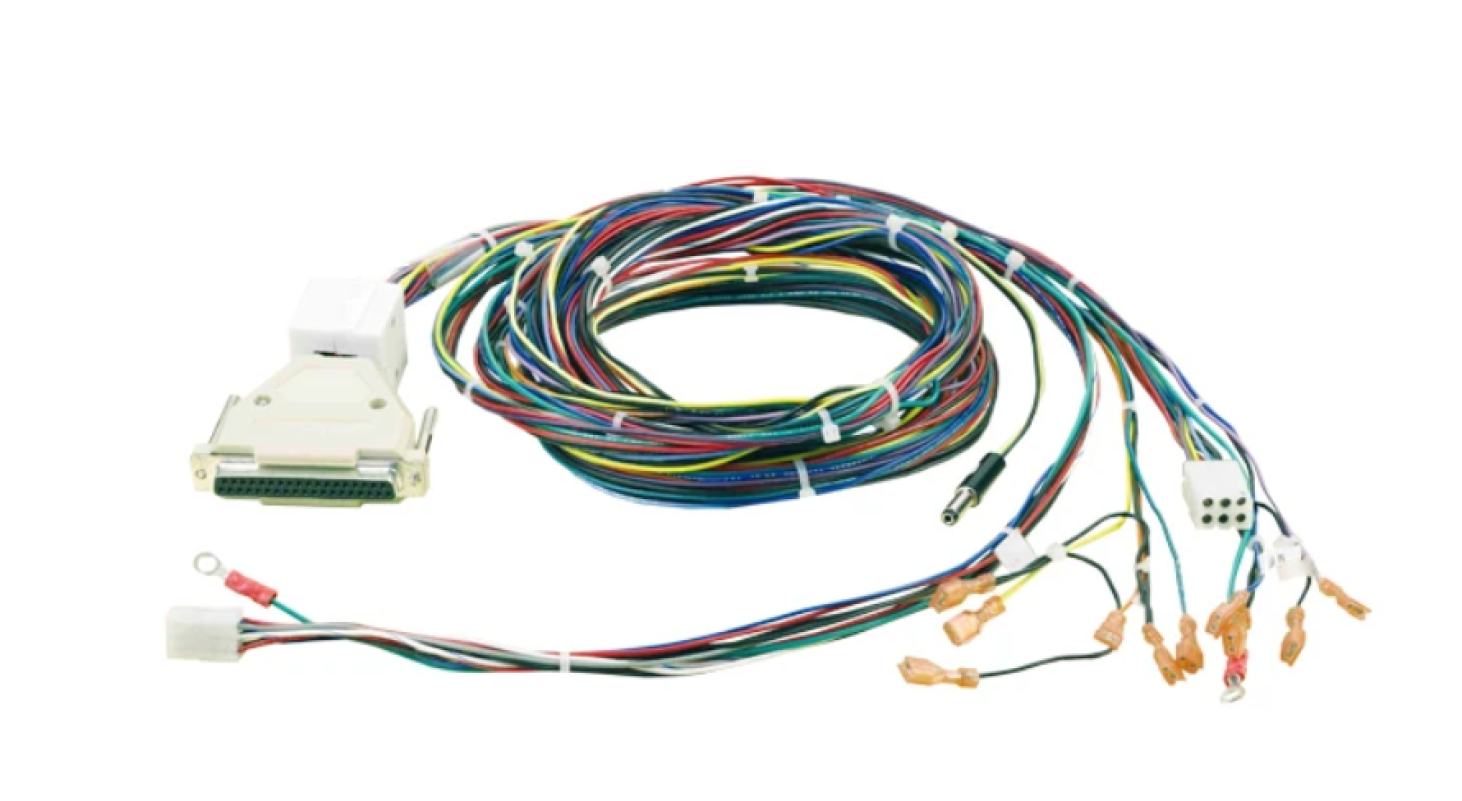

Wire Harness Assemblies

Y.C. Cable manufactures custom wire harness assemblies for automotive, industrial, and medical applications.

Our wire harnesses are engineered to simplify complex wiring systems while ensuring durability, safety, and ease of installation.

We offer full build-to-print capabilities, supporting low to high volume production and a wide range of connector types.

A wire harness assembly is an organized bundle of wires, cables, and connectors designed to transmit electrical power and signals within a system. These assemblies are essential in various industries, including automotive, aerospace, and electronics, where they facilitate efficient and reliable electrical interconnections.

Key Components of a Wire Harness Assembly:

-

Wires and Cables: Conductive materials, typically copper or aluminum, that carry electrical currents or signals.

-

Connectors: Interface devices that join electrical terminations to create an electrical circuit.

-

Terminals: End-point components attached to the wire ends to facilitate connections.

-

Protective Sleeves and Insulation: Materials that shield wires from environmental factors such as moisture, heat, and abrasion.

Benefits of Using Wire Harness Assemblies:

-

Streamlined installation:

Pre-assembled harnesses significantly reduce the complexity of wiring a system, saving time and labor costs during assembly. -

Improved reliability:

By having wires properly secured and organized within the harness, the risk of loose connections, chafing, or short circuits is minimized, leading to better system reliability. -

Enhanced durability:

Proper bundling and protection within the harness can shield wires from environmental elements like heat, moisture, and abrasion, increasing their lifespan. -

Space efficiency:

Wire harnesses allow for compact and organized wiring layouts, maximizing available space within a device or system. -

Ease of troubleshooting:

Pre-labeled wires and standardized design within a harness make identifying and fixing electrical issues much easier. -

Standardization:

By using pre-designed harnesses, consistency across different units or production runs is achieved, simplifying manufacturing processes. -

Cost-effectiveness:

The reduced assembly time and minimized potential for errors due to pre-built harnesses can lead to lower overall production costs.

Applications of wire harnesses:

- Automotive industry: Connecting various components within a vehicle like sensors, actuators, and control units

- Electronics manufacturing: Wiring for complex electronic devices like computers, appliances, and medical equipment

- Industrial machinery: Connecting electrical components within industrial equipment

- Aerospace and defense: Reliable wiring for critical systems in aircraft and military equipment

Wire Harness Assembly Process:

-

Design and Planning: Engineers develop detailed schematics based on the system's electrical and geometric requirements.

-

Wire Cutting and Stripping: Wires are cut to specified lengths and stripped to expose conductive material for termination.

-

Terminal Application: Terminals are crimped or soldered onto wire ends to prepare for connector assembly.

-

Assembly Layout: Wires are arranged on a form board (assembly board) according to the design specifications.

-

Bundling and Securing: Wires are bound together using tape, clamps, or cable ties, and protective sleeves are applied as needed.

-

Testing: The completed harness undergoes electrical tests, such as continuity and insulation resistance checks, to ensure functionality and safety.

Y.C. Cable is a leading manufacturer specializing in custom wire harness assemblies, serving a diverse range of industries including automotive, medical, consumer electronics, and automation & robotics applications.

Wire Harness Assemblies - Y.C. Cable

Established in 1985, Y.C. Cable has built a reputation for delivering high-quality, reliable wire harness solutions tailored to meet specific customer requirements. With ISO 9001:2015 and ISO 13485:2016 certifications, the company ensures adherence to stringent quality standards across its manufacturing processes.

Our Services

-

Custom Wire Harness Assemblies: Y.C. Cable offers bespoke wire harness solutions designed to meet the unique needs of each client, ensuring optimal performance and reliability.

-

Cable Assembly Manufacturing: With facilities in both the United States and China, Y.C. Cable provides comprehensive cable assembly manufacturing services, adhering to IPC 620 and Telcordia GR-326 specifications.

Industries Served

-

Automotive: Specializing in automotive cable assemblies, Y.C. Cable provides solutions such as A/V signal cables, car light cables, and IVI automotive cables.

-

Medical: The company manufactures precision custom medical cable assemblies, adhering to ISO 13485:2016 standards to meet the stringent requirements of the medical industry.

-

Consumer Electronics: Y.C. Cable offers a range of consumer electronics cable assemblies, including MFI certified Lightning cables and USB Type C cables.

-

RF Applications: Providing RF cable assemblies such as I-PEX and FAKRA, Y.C. Cable caters to the needs of high-frequency signal transmission applications.

- Automation & Robotics: YC Cable specializes in custom cable assemblies and wire harness solutions tailored for industrial automation, robotics, and smart manufacturing.

For more information or to request a quote, contact us today.