What Are Cookies

As is common practice with almost all professional websites this site uses cookies, which are tiny files that are downloaded to your computer, to improve your experience. This page describes what information they gather, how we use it and why we sometimes need to store these cookies. We will also share how you can prevent these cookies from being stored however this may downgrade or 'break' certain elements of the sites functionality.

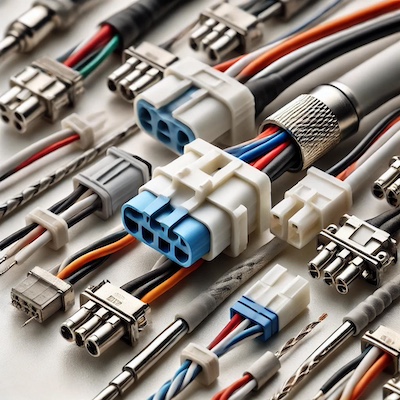

Custom Molex Cable Assemblies

At Y.C. Cable, we specialize in manufacturing custom Molex cable assemblies according to your precise specifications. Using your provided drawings and Bill of Materials (BOM), we ensure that every custom Molex cable assembly meets your technical and performance needs. Our experience spans a wide range of industries, including automotive, telecommunications, and medical, ensuring reliable and durable solutions.

Why Choose Molex Connectors?

Molex connectors are trusted for their reliable, durable design, using a two-piece pin and socket system that ensures secure connections in various applications. These custom cable assemblies are used in a wide variety of environments, such as

- CD/DVD drives

- Hard drives

- Motherboards

- Fans

- Industrial machines

- Telecommunications equipment

Our Capabilities

While we don’t design the cables, Y.C. Cable manufactures high-quality custom cable assemblies based on your provided specifications. We also offer additional support by sourcing all necessary components and helping identify alternative parts when needed, ensuring the custom Molex cable assembly is completed on time and on budget.

Connector Types

We provide an extensive selection of Molex connector types to fit your exact requirements. Our options include:

- Mini-Fit Jr.™ connectors: Ideal for high-current applications and capable of handling up to 13A per circuit.

- Micro-Fit 3.0™ connectors: Compact, suitable for high-density connections with up to 5A per circuit.

- Nano-Fit™ connectors: Designed for space-saving, high-power applications with fully isolated terminals.

- KK™ Series connectors: Versatile, providing both power and signal connections in various pitch sizes, commonly used in consumer electronics.

- MX150™ sealed connectors: Sealed for harsh environments, suitable for automotive and industrial applications.

- SL™ Modular connectors: Ideal for signal integrity in telecommunications and networking.

- FCT D-sub connectors: Used for cable-to-board connections in telecommunication and data systems.

These connector options ensure that your custom Molex cable assembly is perfectly suited to your application.

Conductor Size and Material

We offer multiple options for conductor size and material, ensuring optimal performance for different applications in your custom Molex cable assembly:

- Size Options:

- Small-gauge wires (32 AWG – 24 AWG) for low-power and signal connections.

- Mid-range sizes (22 AWG – 18 AWG) for power and signal transmission.

- Large-gauge wires (16 AWG – 10 AWG) for high-current applications.

- Material Options:

- Copper (Standard): High conductivity for most electrical connections.

- Tinned Copper: Enhanced corrosion resistance, commonly used in automotive and industrial environments.

- Silver-Plated Copper: Offers higher conductivity and resistance to extreme temperatures.

- Aluminum: A lightweight alternative for specific applications with cost and weight considerations.

These conductor materials and sizes ensure that your cable assembly can handle varying power needs efficiently.

Insulation and Jacket Materials

We offer a variety of insulation and jacket materials to suit the environmental and electrical requirements of your custom Molex cable assembly:

-

Insulation Materials:

- PVC (Polyvinyl Chloride): Cost-effective, flame-retardant, and flexible, suitable for a wide range of standard applications.

- PE (Polyethylene): Known for its moisture resistance and excellent electrical properties.

- Teflon (PTFE): Provides superior heat resistance and is used in high-temperature environments.

- Silicone: Highly flexible with excellent thermal stability and chemical resistance, ideal for medical and industrial applications.

- Polyurethane (PUR): Abrasion-resistant with good chemical resistance, suitable for harsh environments.

-

Jacket Materials:

- PVC (Polyvinyl Chloride): Commonly used for flexible cables with good resistance to abrasion and chemicals.

- Nylon: Offers strength, flexibility, and resistance to oils and chemicals.

- TPE (Thermoplastic Elastomer): Provides flexibility and durability, commonly used in industrial and outdoor environments.

- Kevlar® Reinforcement: Adds tensile strength and durability to cables used in extreme environments.

- Halogen-Free Options: Available for applications that require minimal toxicity and smoke in case of fire, especially in public spaces and enclosed environments.

Customization Beyond Standard Options

Our team can also accommodate special requests for additional customizations in your custom cable assembly needs, such as

- Shielding Options: Various types of shielding (braid, foil, or combination) to minimize electromagnetic interference (EMI) for sensitive applications.

- Overmolding: To provide strain relief and extra protection for connectors and junctions.

- Cable Length and Configuration: We can produce any cable assemblies in a range of lengths and configurations, from simple extensions to complex multi-branch designs.

Precision Manufacturing

With Y.C. Cable, precision is at the heart of everything we do. Each custom-made Molex cable assembly is manufactured to the exact specifications provided, ensuring complete alignment with your project’s technical needs. Our production process is backed by strict quality control to ensure your products meet or exceed industry standards.

Partner with Us

Whether you need a small, one-off production or a large-scale order, Y.C. Cable has the experience and capacity to meet your requirements. Contact us today to get started on your project or request a quote.